Emo Systems Network Isolators allow medical equipment designers to design IEC 60601-1 compliant Ethernet for first-pass testing success.

When used in Medical IT systems, our Keystone Modules create electrically safe operating and critical care rooms.

Connect medical equipment to non-compliant networks while maintaining IEC 60601-1 compliance.

Network Isolators for Electrical Safety of network connections according to EN 60601-1

While the security aspects of electrical power installations are widely known in the medical field, one usually thinks first of firewalls and anti-virus software in the case of security of data networks. The measures for the safety of patients also include protective measures regarding data lines. Dr. EU. Berndt from EMO Systems GmbH outlines Technology and Measures.

The danger of electrical shock from copper data lines is often overlooked. This danger is far greater for a patient who might be bound to metal leading parts of medical machines (ME Machines) for therapeutic or diagnostic purposes than for a healthy person. For this reason, particularly high electrical security standards are placed on ME Machines.

In order to ensure that patients are not exposed to harmful currents through data lines, the data lines are equipped with Network Isolators (NI). The form a galvanic isolation spot for the data line in the same way that isolating transformers guarantee this for energy conduction.

In order to keep the costs of safety down, zones with different security requirements are established in the design of the treatment rooms. The zone with the strictest requirements is the so-called Patient Environment (PE). It is a sphere of about 1.5 meters around the patient.

When a Network Isolator is Needed

Data networks usually don’t satisfy the security requirement of EN 60601-1. A direct connection of the ME machine with the Data network creates an ME System which no longer fulfils the requirements of EN 60601-1 and presents the patient with an unjustifiable risk. An NI serves to make possible a data connection between an ME machine, a non-medical machine or a data network, which adheres to the security requirements of EN 60601-1.

About MOP, MOPP and MOOP

In order to give patients a high degree of safety, means of protection (MOP) have been prescribed (MOP = means of protection) by the EN 60601-1, which must be implemented by machine manufacturers. EN 60601-1 prescribes two independent means of protection in the patient environment. Beyond that, there are requirements concerning Isolation construction, constructive gaps, material requirements, but also requirements concerning earthing connections etc.

2 MOPP mean, for example, two constructive measures, that is, a particularly safe means of protection. The failure of one does not give rise to danger to patients because of the existence of the second means of protection. MOPPs should be differentiated from the weaker MOOPs (means of operator protection). MOPPs must be differentiated from the weaker MOOPs (means of operator protection). The machine manufacturer must define the MOPs and allocate MOOPs and MOPPs through risk assessment, relying on the regulations of EN 60601-1.

MOP, MOOP and MOPP can be said to be the safety building blocks. They have no dimensions and only gain physical form through further border and environment conditions.

NI, with 1 MOPP can be used when the ME-Machine already exhibits 1 MOPP in relation to the data connection, for example through a strong connection of the MEMachine’s casing with the earth. If this is unclear, the implementation of an NI with 2 MOPP is provided.

The indication of whether an NI forms one or two protective measures for patient protection can seldom be found in the product description of the producer. Instead, proof voltage is often discussed (1 MOPP: ≥ 1,5 kV, 2 MOPP: ≥ 4 kV). However, far from all NI applied with ≥ 4 kV fulfil the technical requirements of 2 MOPP, which, among other things, require a costly conduction construction and only worsen the conduction characteristics minimally.

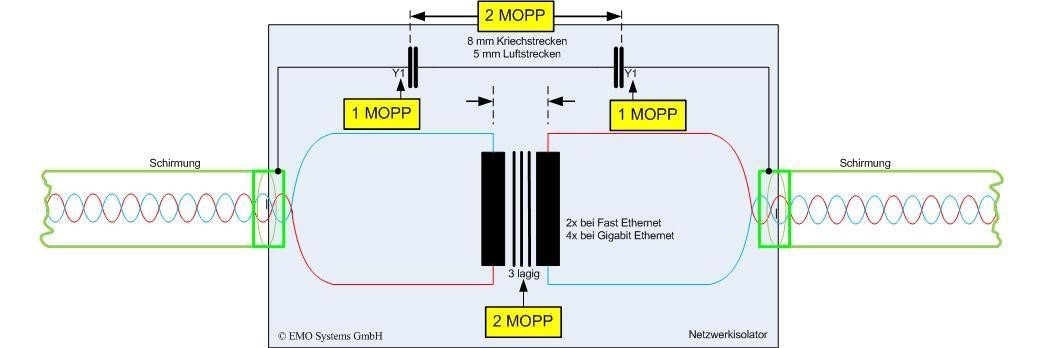

A passive, inductive Network Isolator with 2 MOPP

This NI possesses one 1:1 impulse-transformer (conductor) for every signal cable pair. Protocol-independent conduction ensues without an SW Driver. Because of the inductive coupling, however, no DC gauges can be transferred. The shielding of the data lines between the entrance and exit of the NI is interrupted and eventually shortcircuited through high frequency capacities when high frequency transients must be suppressed.

The formation in the shape of an isolation diagram is schematically presented in Image 1.

According to EN 60601-1, 3rd edition, 2 MOPP require the combination of a 3 layered winding isolator, a content of 8 mm creeping path and a 5 mm air gap, as well as the use of two Y1-condenser in case an EMV-Measure is desired.

If a parameter of this is not maintained, the NI no longer possesses 2 MOPP!

In a 1 MOPP System the single-layered basic insulation can be used.

Types of Construction

NI are available in three construction types.

The most common type of construction involves an NI in an individual casing, which, through the aid of an additional patch cable is employed in the data line that has to be protected. For its spatial requirements the following applies: as close as possible, but outside the PU!

In a further construction type, NI form in wall outlets. This is considered an interesting variant insofar as the treatment room is completely equipped, the building installation is carried out conscientiously and the long data line for possible cleaning and disinfection processes within the treatment room is of good quality.

Thirdly, in some ME machines, an NI is already built in. In most mobile machines, the insecure data cable should be connected in a contact secure way.

Often, a patch panel with incorporated NI is required. However, this goes against the requirement found in EN 60601-1 according to an as immediate as possible proximity of the NI to the machine which is plugged in; therefore, it cannot be recommended. The danger of damages to or mix-ups with the data lines between the patch panel and the outlet in the cable channels exists.

NI are available for 10/100/1000 Mbit/s Data rates. Especially in the case of comprehensive new installations, future data rates should be taken into consideration and Ni should be implemented with a high transfer rate.